Lean Culture and the Six Sigma Process

What is the Six Sigma Process?

|

Six Sigma refers to a set of quality management methods that are integrated into a company’s sales, service and manufacturing sectors. These methods identify and remove product defects, while streamlining business processes from customer engagement to delivery and service guarantee.

In the wake of the widespread global popularization of the Six Sigma Process, a culture based on efficiency, quality and customer service--or a lean culture, is transforming the way companies do business, by eliminating any processes or procedures that do not enhance customer value and experience. At the same time, value added practices customers find appealing, such as fair pricing, helpful customer service, and expedient delivery of products are implemented as a plan-of-action for increased business success. |

“Six Sigma is a systematic process that is used to improve the capability of business processes by strategically reducing redundancy and other forms of inefficiency. It accomplishes this while eliminating defects in any sales, service, manufacturing-industrial or corporate processes. This results in a proactive, customer oriented, dynamically flexible, and profitable corporate culture that benefits your bottom line and customer satisfaction alike.”

Pat Lucansky, CSSMBB, CLS, CMC Executive Director, VIP Group |

The Five Phases of the Six Sigma Process

|

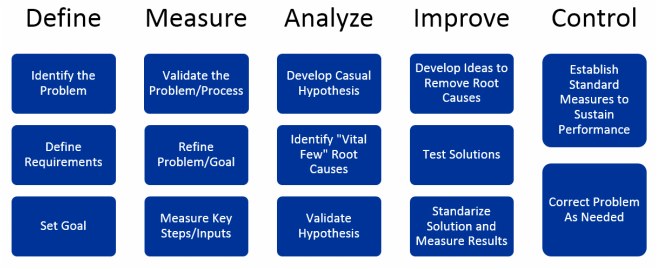

This Six Sigma Process is a five phase methodology for continuously improving quality by reducing inherent variability. The five main phases are:

|

The general Six Sigma Process can be further refined and individualized to suit the needs of which specialized Lean Culture facet is being focused on:

What is the History of Six Sigma Process?

The history of the Six Sigma Process differs depending on who you ask. To be as thorough as possible for your educational benefit, we have traced Lean Culture from its inception to today:

- The discovery of the Six Sigma Process as a measurement standard is credited to Carl Friedrich Gauss (1777-1855), who introduced the concept of the normal curve.

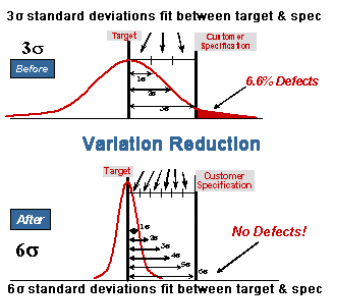

- In the 1920’s, the Six Sigma Process as a measurement standard was employed by Walter Shewhart, who showed that three sigma from the mean (standard) is where a process requires correction.

- The actual coining of the term Six Sigma, and canonizing of the (now) generally accepted process, is due in large part to a Motorola engineer named Bill Smith (in fact, the term Six Sigma is a registered trademark of Motorola).

What is the Formula Behind the Six Sigma Process?

The Six Sigma Process strives for 99.99966% of every opportunity to produce some feature of a part, to be statistically expected to be free of defects. This means that instead of measuring defects in the thousands, the Six Sigma Process standard dictates that opportunity for defect should be no more than 3.4 defective features per million opportunities. So in this regard, the Six Sigma Process means tremendous precision--and it is orders of magnitude ahead of the traditional quality management protocols the Motorola engineers found wholly insufficient for their needs, as well as the expectations of con

Let Our Lean Culture Experts Put Six Sigma to Work for You

Contact us today, and our Lean Culture team will begin assessing and implementing a Six Sigma Process program that benefits you and your customers—as well as increases your profit margin from top to bottom.

About VIPGroup’s Six Sigma and Lean Culture Consulting Services

Value Innovation Partners Ltd. specializes in Six Sigma and Lean Culture implementation for businesses of all sizes and specificities. Our Lean Enterprise and Operations Improvement Experts are known throughout the corporate world for their expertise, precision, professionalism and high success rate. We have helped implement and maintain streamlined operations, industrial, manufacturing and customer service-based practices in businesses just like yours. Contact us today to see how your business, your customers, and your bottom line can immediately benefit from our experience.