Quality Part 2

Quality – What does it really mean to you, your organization and your customers?

|

Because the company knew that there would be damage to the material, it used variances to cost against. If 100 cans were required, enough material for 100 cans (plus some extra) was launched into the process and the company would hope that, at least, 100 usable cans would be produced. Sometimes they were, sometimes they were not. Consequently the company never had any confidence that it could meet an order accurately. On a good day 100 cans might be produced with only 4 scrapped against an allowance (or standard) of 8.

The company would celebrate that there was a positive variance of 4 below standard instead of asking why the material for four extra cans was lost. On a bad day, 100 cans might be produced from the material for 110 cans. The company would rationalize its failure by saying "We were only 2 over standard" (a negative variance of 2) instead of recognizing reality and admitting to having wasted a surplus of 10 cans’ worth of material. All of the extra activity and accountancy effort adds cost and not value to the product. Since it is generally unaccounted for (what is termed, “hidden factory”), it will silently erode margins and increase complexity. Ultimately, it is the customer who pays for the extra costs in longer lead-times, higher unit prices and lower quality. As a result, the company needs to improve its process capability and reliability which will bring about improvements in output since machine time will not be used to produce unusable product. Next the company needs to improve its process flow and reduce the amount of handling while installing systems to document procedures and standardize work. Cost of Quality AnalysisQuality costs can be expressed in a number of ways. Many companies measure the cost of scrap and of rework but relatively few companies measure the cost of inspecting out the sub-standard product. Even fewer companies measure, or are able to measure, what is spent on prevention. The amounts spent on prevention tend to be less than those spent on inspection. Because, generally, there is little investment in preventing things going wrong in the workplace, however, things do in fact go wrong in the workplace.

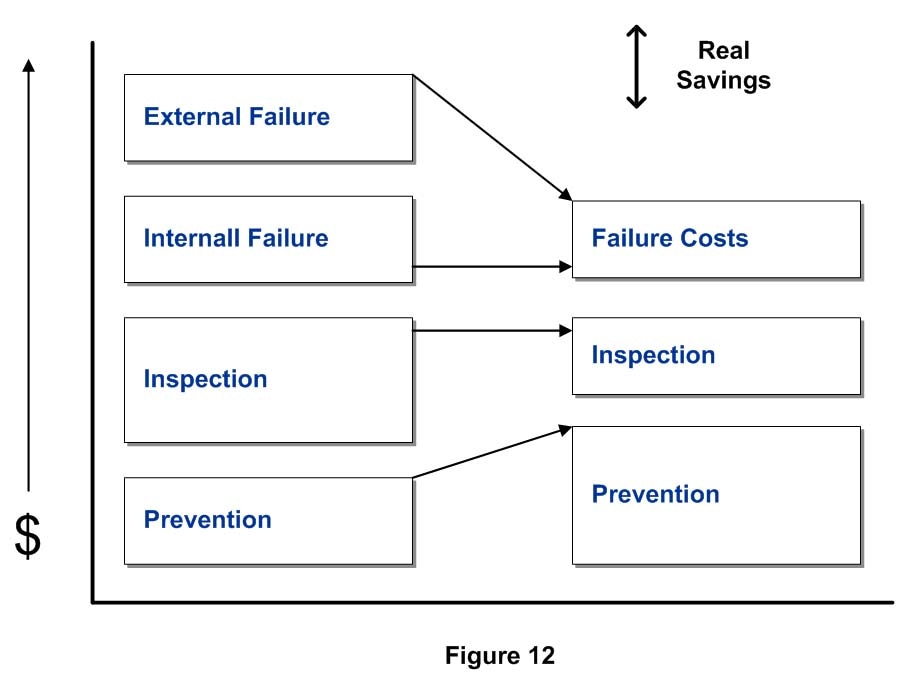

When things go wrong, additional costs are generated in finding the consequences of the mishap i.e. the inferior product is inspected out and separated from acceptable production. If this can be done successfully, the costs of finding the inferior product and putting it right are internal failure costs. There is a chance, however, that not all of the inferior product will be found and some will escape into the market place. The result is, perhaps, a customer complaint and an external failure cost (warranty claim). The total of these cost categories can be as high as 36% of a company’s turnover! Figure 12 shows the effect of increasing the amount of money spent on prevention. If more money is spent on prevention, i.e. preventing things from going wrong, there is less likelihood that events will go wrong. Therefore, there are fewer requirements to search for, and arrest, inferior quality, so inspection costs will be reduced. Consequently, there is less to find and correct, so internal failure costs are reduced and, because there is less inferior quality within the business, there is a lower probability that inferior quality can escape into the market place, thus reducing the external failure cost.

The difference in height between the column on the left and the column on the right in Figure 12 represents real savings for a business which will tumble through straight onto the bottom line. Apart from the cash, there are other benefits for a business. Because quality is reliable and consistent, repeat purchases will be encouraged and customer loyalty engendered. Loyal customers will introduce new customers and thereby increase the company’s market share. This extra market share is stable because it has been earned (i.e. It is based on a solid foundation of customer goodwill) rather than having been bought by discounted prices, promotions and special offers. Simultaneously, the company’s cost base has been reduced. Quality BenefitsWhy bother? Why bother with any of this? Why subject a business to the uncertainty of change? Why challenge the traditional thinking of a company or organization? Why should a company try to find better ways of doing things? The answer is MONEY. Every business exists to make money. There is no other reason. If we review Case Study No 2: The Food Manufacturer, observe the benefits that the company achieved by altering one small and insignificant part of its business processes.

Their space requirement is reduced by 75%. Instead of four areas holding mushroom stock there is now only one. Heat, light and power costs are reduced by 50%. Instead of using two refrigeration units, they now only need to use one. The asset base is reduced by 75%, if space is considered as an asset, but also the capital investment requirement is reduced since, prior to the change, a fork lift truck was needed to move the mushrooms whereas, now, only a hand truck is required. The labor requirement from the warehouse is removed completely. Previously, two warehouse men were employed to move the mushrooms, now the mushroom delivery man puts the mushrooms into RU 4 and the production department staff removes the mushrooms. Productivity has increased because the same amount of product is being handled without the two warehouse men who have been deployed elsewhere. Cash flow has been improved because instead of holding four day’s stock of mushrooms there is now only one day’s stock. The cash flow value of three day’s mushroom stock has been freed up for the company to spend or invest in other ways. What has all this got to do with quality? Here is the rub! The quality of the product to the customer is improved because the mushrooms are only one day old at the point of use instead of four. The customer is receiving a fresher product which in turn must be of better quality. If the supplier can produce a better quality product with lower costs, the supplier must be more competitive than it was previously. The benefits, or cost savings, outlined above will tumble through to the bottom line. The company has reduced its cost base and improved its margins. It is now in the enviable position of deciding whether it should pass on the improved profit margin to its shareholders, or should it reinvest, or should it offer bigger discounts to its customers? A difficult choice, but more enjoyable one to make! The biggest advantage is yet to come! The supplier, at the time of operating the system shown in Figure 6 had a difficulty with its customer in so far as they could not supply to order. This is hardly surprising since mushrooms to be used on Friday, had to be ordered on the previous Friday for delivery on Monday and entry into the system. The customer only provided its orders on Wednesday for Friday delivery. The customer was demanding a two day order cycle while the supplier wanted the customer to give seven days’ notice. Consequently, the supplier had to guess the quantity of mushrooms to order on Friday of week 1 for use on Friday of week 2. Therefore, the supplier always had the wrong amount of mushrooms in the system. There were either too many or too few. Too many meant that mushrooms were wasted, incurring more cost, too few meant that the order was short. By adopting the system shown in Figure 7, the supplier could wait for the order on Wednesday and order the exact amount of mushrooms required for delivery on Thursday for use on Friday. The customer was delighted that it received exactly the product quantity required. The supplier is now operating on a much shorter lead time and therefore is much more responsive to the demands of its customer. The lesson, in any industry, is to provide "fresher" product. Methods must be sought to drive out stacked lead time, reduce stock holdings (cut short the aging process) and take advantage of all of the benefits shown in this example. All of the items in the left hand column below reduce while all of the items in the right hand column increase:

Our argument is that if this can be achieved in one small insignificant part of the business, how much could be achieved by applying the same principles to the rest of the business?

The Improvement ProcessAttainment of the benefits highlighted in the previous section can be brought about by the implementation of this simple 5 step process which can be almost universally applied.

Step 1: Exposing the ProblemIt has long been said in problem solving, that in order to solve a problem one must first identify the problem. Exposing the problem is somewhat different. All too often the problem is known, but remains hidden for a variety of reasons. A problem may be viewed as an obstacle that prevents people from achieving and, as with any obstacle; one can go over it, under it, round it or through it.

|

By far the simplest course of action is to remove the obstacle completely so that people can be allowed to achieve unhindered.

We see the manager’s role as removing obstacles. If the manager fails, the people tend to work around the problem and still achieve, perhaps not as effectively, but, nevertheless, do achieve the task. In this case, the problem is not the priority it would be, were it to prevent the task being achieved at all and, therefore, remains hidden. By exposing the problem, it is turned into the priority it deserves to be, in order to allow it to be given the attention it deserves. By allowing the problem to remain hidden the company is guilty of wasting resources. An example is the output of a machine where, due to some malfunction, 10% of all output is of inferior quality. The temptation is to keep running the machine because, despite the malfunctioning, the order can still be achieved. In this way, the problem remains hidden and the machine never gets fixed. An alternative is to stop the machine each time it produces a defective part. Once the machine is switched off, the order cannot be achieved so the problem has been exposed and the machine is now a priority and gets fixed earlier. Step 2: Fixing the Non-conformanceIf, as in the above example, a percentage of total output has been identified as being of inferior quality, steps should, at least, be taken to prevent it becoming mixed with good quality output until it can be repaired or reworked in some way and, subsequently, released for sale. In this way, fixing the non-conformance is a temporary stop gap until moving onto the next step in the process. Until the root cause is found, the symptoms will continue to be managed and more resources will be wasted.

Step 3: Finding the Root CauseA simple method of finding the root cause of a problem is to ask "Why?" five times. In the event of a machine breakdown, "Why?" is asked only once and the machine is up and running again as quickly as possible. In the example given below, when the machine stops, "Why?" is asked once, and when it is discovered that the fuse has blown, the manager breathes a sigh of relief that it was nothing more serious, has a new fuse inserted and runs the machine......until it stops again.

If, upon discovering that the fuse had blown, "Why?" was asked for a second time, it would be discovered that the fuse had blown because the motor had overheated. The fuse is, therefore, functioning correctly. If “Why?" was asked (for the third time, i.e. "Why is the motor overheating?"), the answer might be that the bearings had seized. If “Why?" is asked for the fourth time, it might be discovered that the bearings seized because they were dry. If "Why?" is then asked for the fifth time, the answer might be discovered that the oil-ducts were blocked. A solution can then be proposed to prevent the oil ducts becoming blocked.

SOLUTION: Implement a planned preventative maintenance program or cleaning schedule to ensure that the oil ducts remain unblocked.

Step 4: Taking Corrective ActionBy implementing the cleaning schedule to prevent the oil ducts from becoming blocked, the root cause of the problem has been removed. If the oil ducts do not become blocked, the lubrication reaches the bearings which no longer become dry and seize, therefore, the motor no longer overheats, the fuse does not blow, and the machine continues to run. The root cause of the problem has been discovered, a solution has been implemented and the problem has been eradicated.

Step 5: Evaluating and Following-upAfter a suitable period of time, it should be ascertained that the suggested solution was implemented and that the implementation was successful in solving the problem. If the solution worked - great, if it did not, then another solution has to be developed. In this example, the intervals between cleaning have been set at one month. If, during that time, there have been further recurrences of the machine breaking down, the cleaning intervals may have to be adjusted to one week. The effects of the solution can be continually monitored until there is a level of confidence that the problem really has been eradicated. Attention can then be turned to the next problem.

Quality ToolsThere are many other quality tools available to assist companies in their drive for perfection. Market research can be used to identify opportunities for new or enhanced products to satisfy customers© future needs. QFD (Quality Function Deployment) can be used to enable robust product design which ensures that the product meets its performance criteria. Taguchi techniques are powerful experimental techniques to identify the critical process parameters that affect product characteristics. These techniques can be used to allow the process to become reliable. Statistical Process Control (SPC) can then be used to maintain the process under control. Quality Assurance functions can be used to monitor process and product characteristics to ensure conformance. Customer Care programmers can be used to identify and monitor key service criteria.

PhilosophyThe entire philosophy of quality management is based on continuous improvement. The driving force to achieve this is, action taken to prevent recurrence. Consider a workplace with a number of quality problems inherent in it. Each one can be systematically addressed using the improvement process outlined above. It matters not how large or how small each quality problem is, but if it is successfully eradicated, there is one less problem in existence. Therefore, the workplace has improved because there are less quality problems arising, after action has been taken to prevent recurrence, than there were before. Therefore, the quality of output has improved because there are fewer opportunities for failure. Embodiment of the philosophy in the working practice of an organization requires the organization to systematically eradicate causes of failure from the workplace, gaining an improvement each time, and continuously upgrading its quality performance.

Essential IngredientsThe essential ingredients for any performance improvement initiative to be successful are:

Internal OwnershipQuality is not simply the domain of the Quality Assurance department, much less is it a responsibility that can be delegated. Quality is everybody’s responsibility throughout an entire organization from the very highest echelons to the most humble. Everyone has a part to play in achieving excellence. For this reason, ownership is essential. Ownership of the problems, the solutions, the successes, the failures, the ideas for improvement, the action, the implementation, the monitoring and measurement should be held by the people in the functions, the departments, the sections or the teams carrying out the task. If the identification of the problems come from the real owners, the people performing the task, the real owners are much more likely to suggest improvements. If their own suggestions can bring about solutions, the solutions are much more likely to be successfully implemented by the owners. The owners will strive much harder to make their solutions work rather than solutions imposed by an external source.

Commitment from the TopThe moment of truth! Quality should be seen as a strategic issue and treated as such by senior management. If the senior managers of the business are not fully committed to the achievement of the corporate policies, goals and objectives, the project is doomed to failure. The commitment from the top must be there to sustain the momentum in the face of adverse conditions, other priorities and the occasional crisis that might arise. Commitment and belief take courage and single mindedness of purpose to see the implementation through and to defend the difficulties of implementation against the critics.

Managers cannot afford to pay lip service to quality. Actions speak louder than words and if the words of senior managers are not supported by appropriate action, they will fail to demonstrate commitment. If their actions belie their words, the workforce will see the transparencies immediately. The process may well involve casualties. Those managers who, for whatever reason cannot, or will not, give their full commitment to the direction that the company has chosen to go in, should seriously consider their position and ask themselves why they remain. Those that do remain without the necessary conviction should be replaced by others who can, who will, and who have a genuine desire to commit. Driven from the BottomThe whole improvement process should be driven by the local experts, the employees within the business who know the problems, and who can often provide the solutions to quality failures, as they perform their day-to-day jobs. We use an expression in consultancy; "With every pair of hands employed we get a free brain - use the brain!" Involve the people, listen to their suggestions for improvement, act on them, implement them, empower the employees to implement their own improvements in performance. Unleash the collective genius of the workforce and harness their efforts to drive the business onwards and upwards to greater achievements. You may even be surprised at the results!

|